|

||||||||

|

||||||||

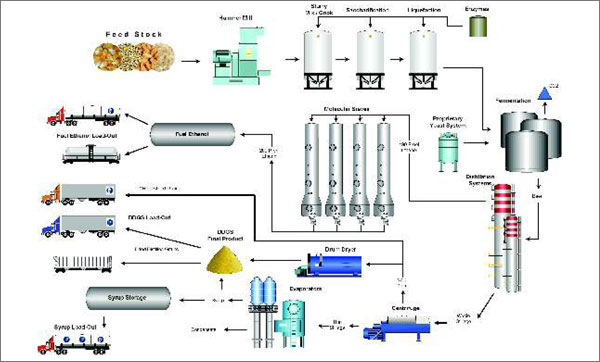

Distillery PlantProduction & consumption of alcohol is an age old practice. But with time, the usage areas as well as production techniques have gone through a major transformation. Apart from potable purposes, alcohol today finds application in a varied mix of industrial areas. And with state-of the-art technology, we now have techniques & systems that bring out much higher quality of the product while effectively lowering production costs. The process of distillation is one with slow dynamics and is accompanied by side streams, making it essential to have a carefully planned and designed control system. Processes

Processes flow diagram

Fermentation

Our Fermentation system design based on crucial parameters which helps to reduce loses of alcohol in fermentors and increase the yield of alcohol by controlling the unwanted by products.

Distillation Process :We offer separation technologies with higher efficient multiple distillation column systems, Which operate at lower energy consumption and higher yield.  Features :

Features :

Dehydration Processes :Molecular sieve dehydration plant design based on pressure swing adsorption with thermal heating to maintain quality norms with advantages.

Zero Liquid Discharge :

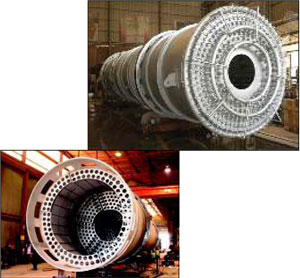

RAJ Zero liquid Discharge Technology provides the most comprehensive, cost effective and reliable operating systems and services. These products and services are designed to help keep your plant safe, and profitable. The Evaporation System consists of single or multiple calendrias (Tubular shell and tube heat exchangers) followed by drying systems. Evaporation systems are designed with consideration of higher fouling fluids, rugged operation, less maintenance and operating cost, easily stable with fluctuation on steam or feed side. For drying we offer rotary and spray dryer considering the suitability and nature of the product to be handle. The dryers are highly efficient having low operating costs and are easy to operate. These dryers are highly effective for products, which required gentle drying and higher residence time. Features of Evaporation Systems

|

||||||||

|

||||||||